Activity Content Sections

Activity 1 Build Materials

Required Materials (per student)

- Assemble One Color Brick and Assembly Line Design Challenge worksheets (8 pages)

- 2 brown paper bags

- 5 pieces of recycled paper 8”x 11”

- 1 full set of colored markers or crayons (be sure to include blue, green, red, orange, purple)

- 1 black marker

- 2 cups of different sizes or other objects that can be traced to make circles (i.e., compass)

- 1 ruler

Required Teacher Materials

- Assemble One Color Brick and Assembly Line Design Challenge worksheets (8 pages) or write brick criteria on a shared board

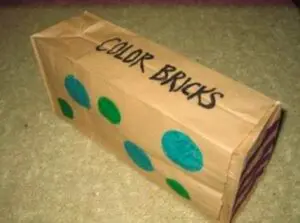

- Sample Color Brick

- Stopwatch, phone or another timer

Activity 2 Build Materials

Required Team Materials

- 30 brown paper bags (30 per team)

- Stack of recycled paper 8”x 11”

- 1 full set of markers or crayons (be sure to include blue, green, red, orange, purple)

- 1 black marker

- 2-4 sets of 2 cups of different sizes or other objects or that can be traced to make circles (i.e., compass)

- 4 rulers

- 1 stopwatch, phone or another timer

Required Teacher Materials

Stopwatch, phone or another timer

The origins of the assembly line can be traced back to miners during medieval times who used bucket elevators to the shipbuilders of the fourteenth century who created moving lines of parts. By the 1900’s the assembly line was used by many industries (shipbuilding, canning, milling, meatpacking, etc.), but was most successful in the automobile industry.

Henry Ford created the Model T automobile in 1908. The car was simple so owners could fix it themselves. It was also sturdy and cheap. Soon, the Ford Motor Company started receiving so many orders for Model T’s that they couldn’t build them quickly enough. To speed up production, Ford changed the way the Model T was built.

Instead of several groups of workers each building a complete car from the ground up, workers stayed in one spot and added parts to cars as they moved past them. Parts were delivered to the employees by conveyor belts. Ford even managed to time the delivery of a part so that it would get to a worker only when it was needed. By 1913, Ford had a complete assembly line functioning. This method of production was rapidly adopted by many industries when they discovered that mass production on assembly lines sped up manufacturing time and lowered costs.

Ford used an approach for his assembly line that we call just-in-time (JIT) manufacturing today. This approach lets manufacturers purchase and receive components just before they’re needed on the assembly line. As a consequence, it relieves manufacturers of the cost and burden of housing and managing idle parts. The basic elements of JIT were developed by Toyota in the 1950’s and were well-established in many Japanese factories by the early 1970’s. JIT began to be adopted in the U.S. in the 1980’s (General Electric was an early adopter) and is now widely accepted and used.

Student Challenge

Students work as a team of engineers to help a local toy company implement time savings methods to manufacture “color bricks.” Each member of your team will design and construct their own brick as quickly as possible. Then, the team will work together to design an assembly line to manufacture bricks as quickly and efficiently as possible.

Success Criteria

- Exhibit the skill to assemble a project by hand that meets the quality control criteria.

- Design an assembly line process to assemble a product as quickly and efficiently as possible meeting the quality control criteria.

- Demonstrate the ability to test and redesign the assembly line process.

- Compare the difference between assembling a product individually versus with an assembly line.

Engineering Constraints

Use only the materials provided.

Instructions

- This lesson demonstrates the power of mass production. The first activity is done individually. For the second activity, break class into teams of 2-4.

Process: Activity 1

Start timer counting up, as you instruct students to begin building their brick. Record the name and time as each student completes their brick.

Process: Activity 2

Set a countdown timer for 10 minutes.

Record how many bricks each team completes.

- Hand out the Assemble One Color Brick and Assembly Line Design Challenge worksheets, as well as some sheets of paper for sketching designs.

- Discuss the topics presented in the Introduce section.

- Review the engineering design process, design challenge, criteria, constraints and materials. Be sure to thoroughly review the “Criteria for Quality Control” and other design criteria outlined in the Assemble One Color Brick and Assembly Line Design Challenge worksheets (8 pages).

- Before instructing students to start brainstorming and sketching their designs, ask them to consider the following:

-

- How to keep quality control, while maintaining efficiency

- What order or sequence do your steps need to be in to make the brick?

- The number of people on your team and the number of tasks that need to be completed

- The differences between assembling a product individually versus with an assembly line

- Provide each student with their materials for activity 1. Then, provide each team with their materials for activity 2.

- For Activity 1: Explain that students must build a brick as quickly as possible using the quality control criteria. For Activity 2: Explain that student teams must build an assembly line from everyday items. Using the assembly line students build as many blocks as possible within 10 minutes using the quality control criteria.

- Announce the amount of time they have to design and build (1 hour recommended).

- Use a timer or an on-line stopwatch (count down feature) to ensure you keep on time. (www.online-stopwatch.com/full-screen-stopwatch). Give students regular “time checks” so they stay on task. If they are struggling, ask questions that will lead them to a solution quicker.

- Students meet and develop a plan for their assembly line. They agree on materials they will need, write/draw their plan, and present their plan to the class. Teams may trade unlimited materials with other teams to develop their ideal parts list.

- Teams build their designs.

- Test the assembly line designs by setting a countdown timer for 10 minutes and recording how many bricks each team completes.

- Teams should document the number of bricks they completed.

Guiding Questions

As a class, discuss outcomes. If necessary, direct the conversation with the following questions:

- Was the order of your assembly line tasks successful? If not, why?

- Did you have enough people in your assembly line to have experts in one task? If not, how would it have changed your assembly line if you had more people?

- Did your group meet the quality control criteria? If not, why?

- Was it hard to go fast and still meet the quality control criteria? What would it take to improve?

- What are the benefits of the assembly-line method when compared to assembling a product individually?

Educational Standards

National Science Education Standards Grades K–4 (ages 4–9)

Content Standard E: Science and Technology

As a result of activities, all students should develop

Abilities to distinguish between natural objects and objects made by humans

Content Standard G: History and Nature of Science

As a result of activities, all students should develop understanding of

Science as a human endeavor

History of science

National Science Education Standards Grades 5–8 (ages 10–14)

Content Standard E: Science and Technology

As a result of activities, all students should develop.

Abilities of technological design

Understandings about science and technology

Content Standard G: History and Nature of Science

As a result of activities, all students should develop understanding of

Science as a human endeavor

History of science

National Science Education Standards Grades 9-12 (ages 14-18)

Content Standard E: Science and Technology

As a result of activities, all students should develop

Abilities of technological design

Understandings about science and technology

Content Standard G: History and Nature of Science

As a result of activities, all students should develop understanding of

Historical perspectives

Next Generation Science Standards Grades 3-5 (Ages 8-11)

Engineering Design

Students who demonstrate understanding can:

3-5-ETS1-1.Define a simple design problem reflecting a need or a want that includes specified criteria for success and constraints on materials, time, or cost.

3-5-ETS1-2.Generate and compare multiple possible solutions to a problem based on how well each is likely to meet the criteria and constraints of the problem.

Next Generation Science Standards Grades 3-5 (Ages 8-11)

Engineering Design

3-5-ETS1-3.Plan and carry out fair tests in which variables are controlled and failure points are considered to identify aspects of a model or prototype that can be improved.

Next Generation Science Standards Grades 6-8 (Ages 11-14)

Engineering Design

Students who demonstrate understanding can:

MS-ETS1-2 Evaluate competing design solutions using a systematic process to determine how well they meet the criteria and constraints of the problem.

Standards for Technological Literacy – All Ages

Technology and Society

Standard 7: Students will develop an understanding of the influence of technology on history.

Design

Standard 10: Students will develop an understanding of the role of troubleshooting, research and development, invention and innovation, and experimentation in problem solving.

Leave feedback form

Thank you! Your submission is processing.