Materials

Instructions

Guiding Questions

STEM Connections

Enjoy this activity?

Join our community and receive activities, early access to programs, and other special news, and/or leave feedback on this activity below!

DiscoverE helps create activities like this around Structures for children in Elementary School and Middle School to help prepare them for STEM careers in fields like Civil or Mechanical.

Students get a taste of what professional engineers face as they work under deadline and within budget and design constraints to construct a structure that adheres to specific performance requirements.

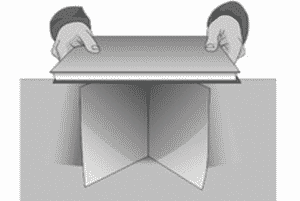

Students get a taste of what professional engineers face as they work under deadline and within budget and design constraints to construct a structure that adheres to specific performance requirements. Explain the rules and design constraints:

Explain the rules and design constraints: Students may weigh and measure the load (the book) at any time during construction.

Students may weigh and measure the load (the book) at any time during construction.

Thank you! Your submission is processing.